Ground Improvement for Warehouse

Project

To consolidate foundation soil for a large warehouse facility in California, Keller installed wick drains and followed up with deep dynamic compaction and surcharging.

Monitoring Requirement

Monitoring the progress of consolidation required easy access to continuous measurements of pore-pressure and settlement.

Implementation

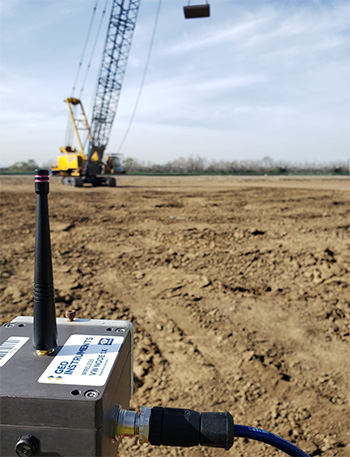

Vibrating wire piezometers were installed across the site. Wireless logger nodes placed at the surface termination of the piezometers relayed pore-pressure measurements to a website for convenient access by engineers. The self-powered, wireless nodes eliminated the time and expense needed for installing, protecting, and repairing power and signal cables running to a central logger.

Settlement plates provided a direct measure of settlement. Riser pipes from the plates were fitted with prisms that were monitored at 4-hour intervals by a solar-powered AMTS system.

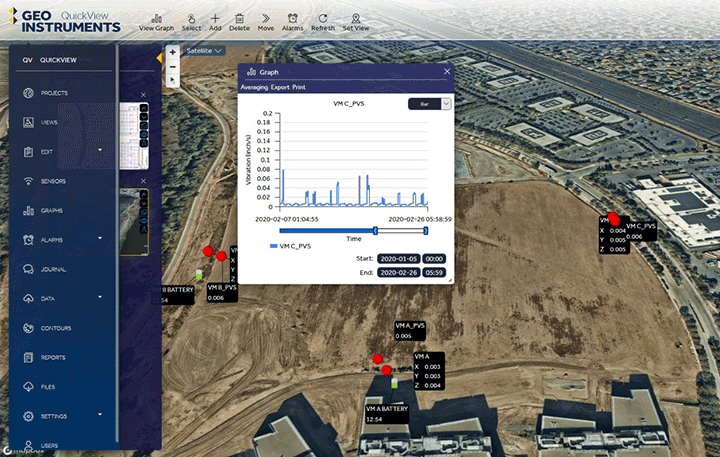

Automated vibration monitors were also deployed during the dynamic compaction work. The automated systems operate 24/7 and provide updates more frequently than is possible with manual methods. Data can be viewed on line via a secure website.