Vibration Monitoring Equipment

Vibration monitoring systems record vibrations from construction activities to check for excessive levels of vibration. Automated vibration monitors transmit measurements to a GeoCloud project website, which sends out alerts as needed, displays vibration data, and generates PDF reports.

Vibration Monitoring Hardware

Vibration Monitoring Software & Services

Vibration Monitoring Equipment - Basic Components

Triaxial Geophones

The triaxial geophone contains three sensors, each oriented to respond to particle motion in one of three vectors: transverse, vertical, and longitudinal.

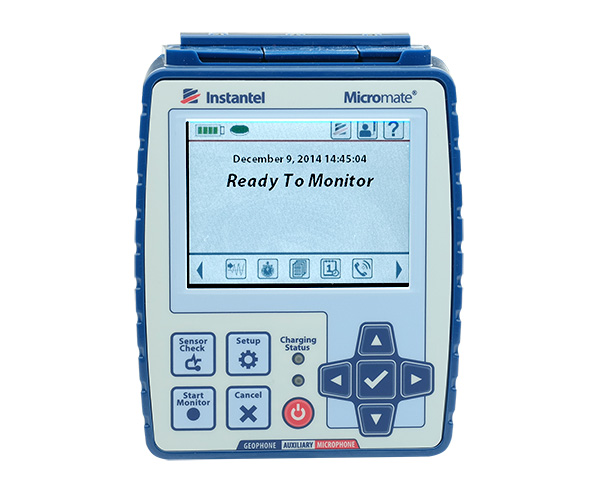

Vibration Monitors

The vibration monitor powers the geophone, converts its signals to particle velocity, and checks peak particle velocity against preset limits.

Processing Software

Processing software imports data from the vibration monitor and generates compliance reports with histograms, waveforms, and limit graphs.

Geophones & Other Sensors

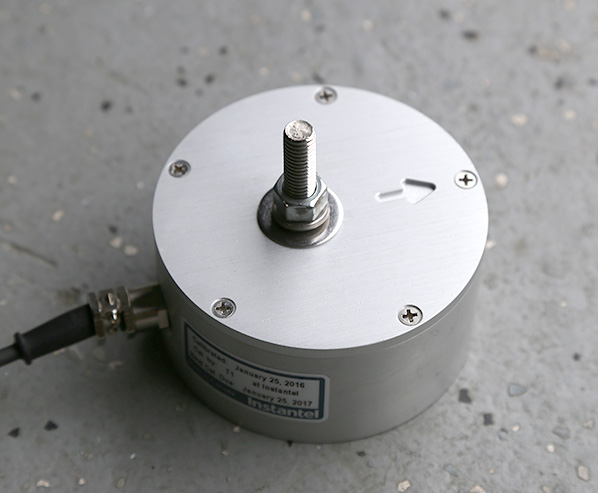

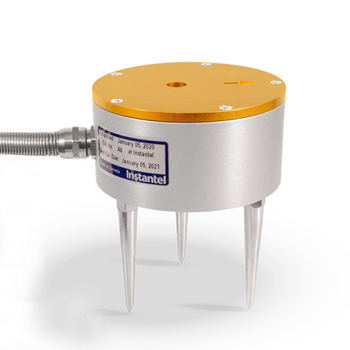

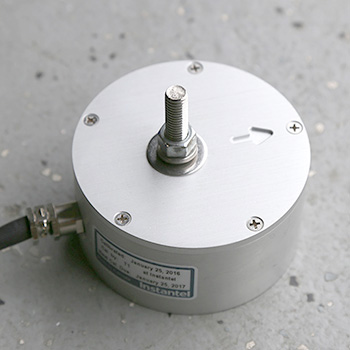

Standard Triaxial Geophone

The standard triaxial geophone is suitable for monitoring almost all construction vibration and blasting.

Standard geophones can be installed in the ground near affected structures or anchored directly to the structures.

- Calibration Standard: ISEE 2017

- Frequency Range: 2 - 250 Hz

- Velocity Range: Up to 10 in/s

- Vertical version available for installation on walls

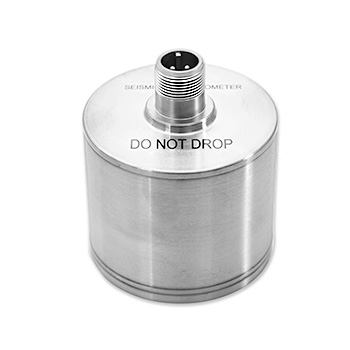

Triaxial Borehole Geophone

Construction vibrations may impact subsurface structures such as tunnels, utilities, and sewers. Direct access to these structures may be difficult.

The geophone is installed in a small-diameter 3" borehole drilled close to the subsurface structure.

- Calibration standard: ISEE 2017

- Frequency Range: 2 - 250 Hz

- Velocity Range: Up to 10 in/s

Microphone

Sound level microphones are tuned for sounds that humans can hear.

- Calibration Standard: IEC 61672-1

- Frequency Weighting: A or C

- Frequency Range: 10-20 kHz

Linear microphones measure air overpressure and are used for blasting.

- Calibration standard: ISEE 2017

- Frequency Weighting: Linear

- Frequency Range: 2-250 Hz

Specialized Sensors

Accelerometers .5g, 50g, 100g

0.5 g accelerometers are used to measure vibrations impacting sensitive medical equipment, chip manufacturing facilities, etc.

- Amplitude Range: 0.5g

- Frequency Range: 0.5 Hz - 500 Hz

- Trigger Level: 0.00032 g

High Frequency Geophone

- Amplitude Range: 100 in/s

- Frequency Range: 30-1,000 Hz

- Trigger levels: 0.05 - 100 in/s

Vibration Dose Value Geophone

- Calibration Standard: DIN 45669-1

- Frequency Range: 1-80 Hz

Hydrophone

The hydrophone is used to measure overpressure in water. Hydrophones are uniaxial.

- Amplitude Range: 47 psi

- Frequency Range: 8 - 500 Hz

- Max Depth: 150 feet

- Trigger Levels: 0.0234 - 47 psi

Vibration Monitors / Seismographs

Standard Vibration Monitors

Basic Functions

The vibration monitor samples signals from the triaxial geophone continuously, checking incoming values against limit thresholds.

The monitor stores the peak particle velocity (PPV) value for each vector at regular intervals. These values are used to generate a histogram report later.

If any incoming value exceeds the limit threshold, the monitor records all of the incoming values for a few seconds. These values are used to generate a waveform report.

Sample Rate & Recording

- Sample rate: up to 4096 S/s

- Trigger thresholds: 0.02 to 10 in/s

- Event recording: 60 seconds

- Data storage:

Sensor Support

Accepts 1 standard triaxial geophone and 1 microphone.

Data Transfers

Supports manual data transfers via a USB cable or flash drive.

Provides firmware support for wireless data transfers by cell modem, but does not supply the necessary hardware.

Advanced Vibration Monitors

Basic Functions

Same as standard monitor

Sample Rate & Recording

- Sample rate: up to 65,536 S/s

- Trigger thresholds: 0.02 to 10 in/s

- Event recording: 120 minutes

- Event storage: 8,000 events

- Zero dead time between events

Environmental

- EMI shielding

- Built-in noise and anti-aliasing filters

- IP67 cast-aluminum case

Sensor Support

Standard or specialized sensors in various combinations

- 2 triaxial geophones

- 1 geophone and 1 microphone

- 6 hydrophones

- 6 accelerometers

Data Transfers

Supports manual data transfers via Ethernet, USB cable, or flash drive.

Provides firmware support for wireless data transfers by cell modem, but does not supply the necessary hardware.

Hardware Enhancements

Solar power, wireless communications, and protective enclosures can increase efficiency and reduce costs.

Batteries & Solar Power

Supplemental batteries provide longer operation in all weather conditions. Solar panels keep batteries charged for even longer deployments.

Wireless Communications

Cellular modems transfer recorded data to the internet at regular intervals, eliminating the need for visits by a field technician. Wireless transfers also make timely alerts possible.

Protective Enclosures

Lockable, weatherproof enclosures hold vibration monitor, batteries, and modem. The enclosures allow the vibration monitor equipment to be left on site rather than collected at the end of the day. Various configurations are available:

- Portable and waterproof

- Semi-portable with solar panel

- Wall mounted, AC or Solar

- Heavy steel with shatterproof solar panels for exposed areas.

Processing Software & Compliance Reports

Processing Software

- Vibration monitors output their recorded measurements in binary code that can be parsed only with specialized processing software (Excel will not work).

- The software imports and processes data from the vibration monitor and then generates compliance reports that include limit charts, histograms and waveform plots.

- User can select from a wide variety of compliance standards.

- Compliance reports can be printed or output in standard file formats, such as PDF or CSV.

- The software or an add-on software module usually supports FTT and other analysis tools.

- Some software provides an API that allows developers to integrate vibration data into a broader geotechnical monitoring platform, such as GeoCloud.

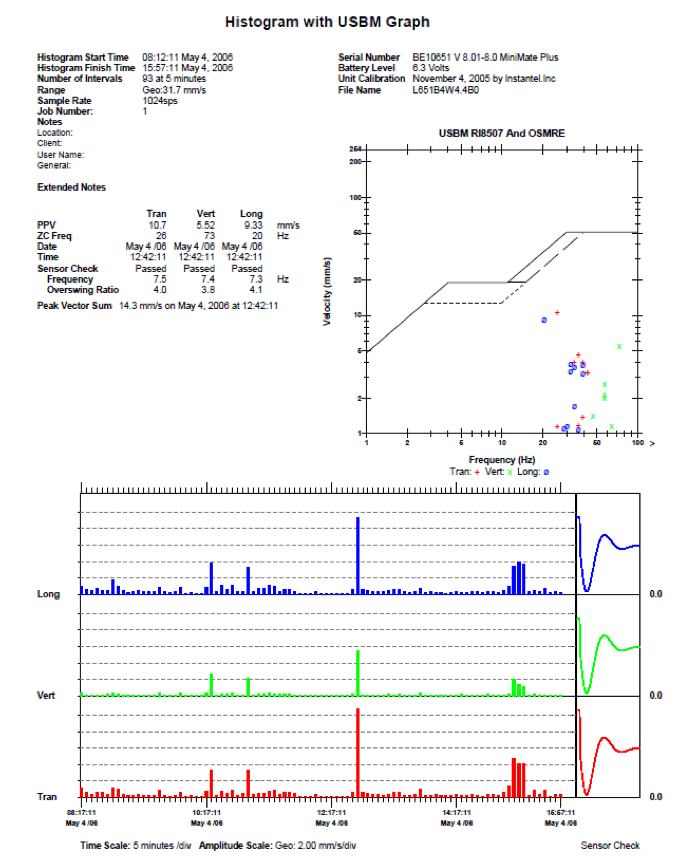

Histogram Report

The histogram report shows the peak particle velocity measured during successive time periods.

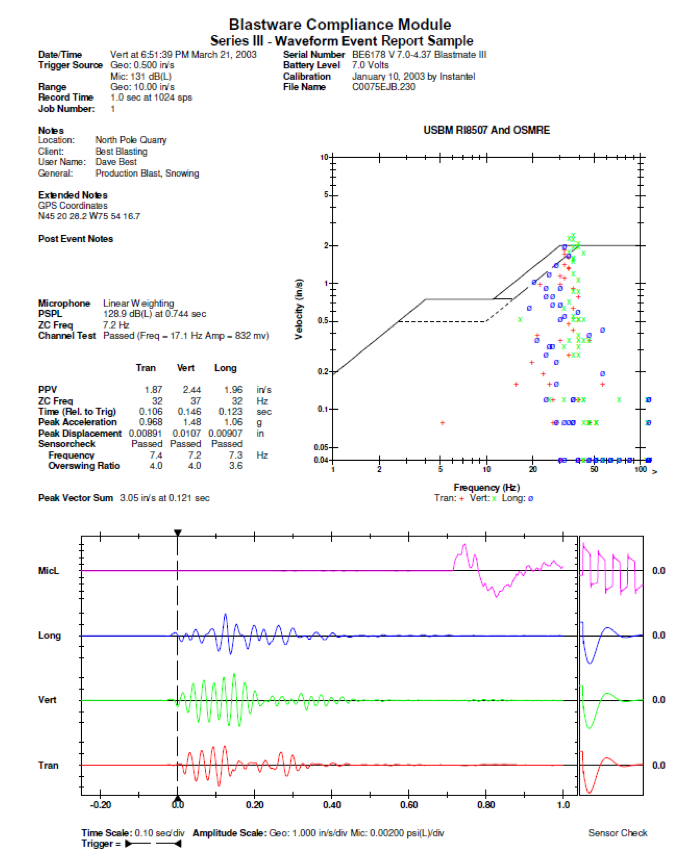

Waveform Event Report

The waveform event report shows a single event, typically triggered by a limit exceedance.

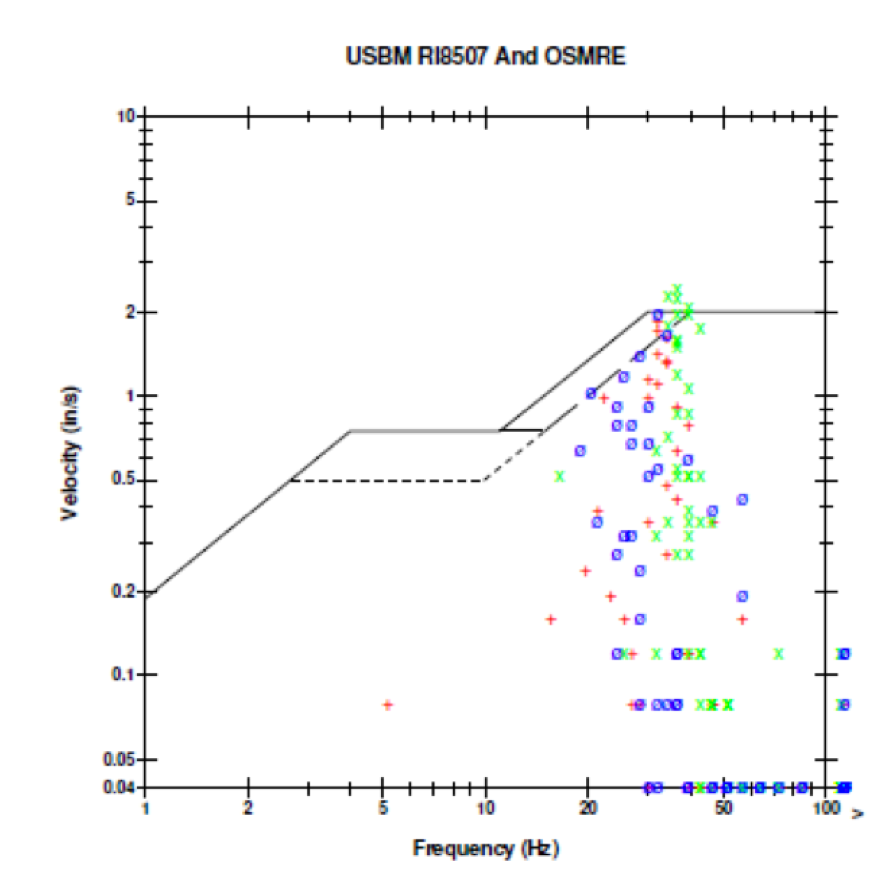

Vibration Limit Chart

The USBM RI 8507 vibration limit chart plots particle velocity against frequency and includes a safe-limit line.

Points above the limit line are potentially damaging. Points below the limit line are considered non-damaging.

Although intended to define safe limits for surface blasting and residential structures, the graph is widely used for construction vibrations and other types of structures.

Automated Vibration Monitoring

What is Automation?

Automated monitoring is a mix of hardware, software, and services that provides better data and eliminates nearly all the manual tasks related to data collection and processing.

Datasheet

Hardware

Hardware required for automation typically includes supplementary power, wireless modems, and protective enclosures.

Automatic Data Uploads

Cellular data services are required for data transfers, which typically occur 4 or 5 times per day, or immediately if measurements exceed vibration limits.

Automatic Processing

The website automatically imports incoming data into its processing software and generates histogram and waveform reports.

Timely Alerts

Alerts for vibration exceedances are displayed on the project website and can be sent to smartphones and PCs.

Easy Access to Reports

The website stores compliance reports for easy access by pc or smartphone. Nothing gets lost.

Data Integration

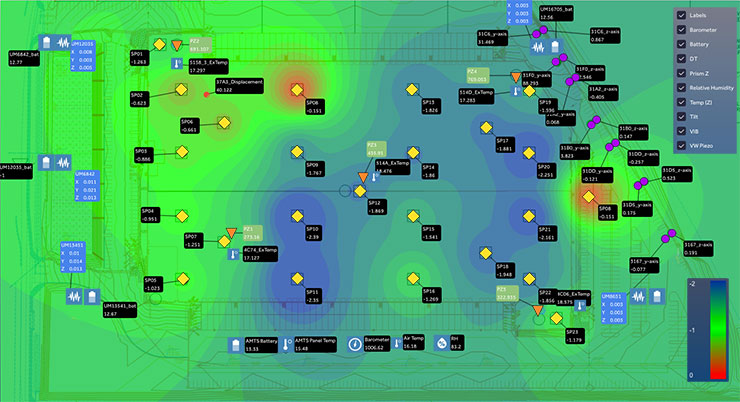

Vibration monitoring is often part of a larger monitoring program, that includes crackmeters, tiltmeters, shape arrays, utility monitoring points, and automated total stations. The website can display the status of all of these on the same screen.

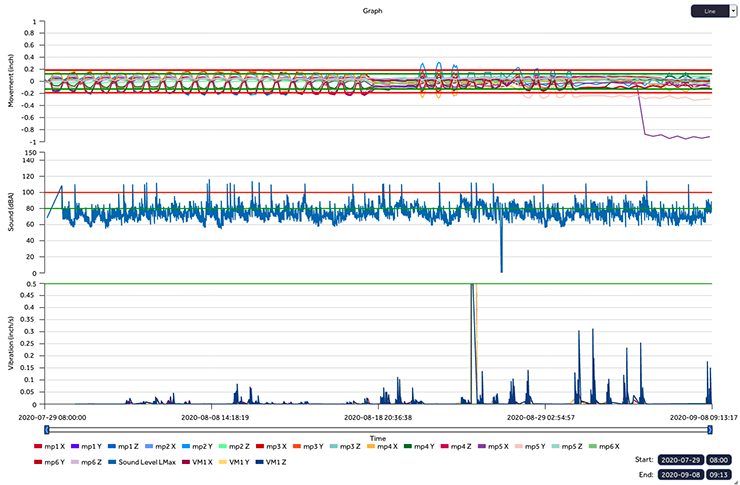

This plot from GeoCloud Quickview shows movement recorded by an AMTS system, noise levels recorded from a sound level sensor, and vibrations recorded from a geophone.

This status screen from GeoCloud Quickview is another example of data integration. A single screen shows settlement, tilt, peak particle velocity (blue boxes), pore-water pressure, and weather conditions.

Frequently Asked Questions

Is Automation Cost-Effective?

We always recommend automation for any location that is difficult to access or that requires special safety precautions, such as tunnels and railways. This leads to time savings as well as better safety.

We also recommend automation services for longer term projects. The accumulated time and cost savings can be significant:

- Fewer maintenance visits (battery charging, data transfers, managing system memory)

- Reduced computer time ( importing data from a memory stick, generating reports, and distributing the reports)

How many geophones can I connect to one vibration monitor?

Typically just one. The spec sheet may list "4 channels," but the triaxial geophone occupies three channels, and the microphone takes the last one. So 1 geophone and 1 microphone.

A few vibration monitors offer connections for two geophones and two microphones, but those are intended for specialized monitoring where, for example, one geophone is installed on a structure and the other on the ground in front of the structure.

Are extension cables available?

Yes, 32, 100, and 250 foot extension cables are available. However, we recommend keeping cables as short as possible. Short cables are less susceptible to electronic noise and less likely to be damaged by construction activities.

Geophone cables are not designed for traffic. If you must route a cable across a road or driveway, we recommend protecting it with a traffic-rated mat or through a trench, if possible.

How are geophones installed?

Detailed instructions are available from manufacturers as well as published guidelines from the ISEE and FTA. In general, the geophone must be level within 10 degrees of horizontal and the arrow should point toward the source of the vibration.

Ground Installation

Most geophones include screw-on spikes to improve coupling with the ground. For short term monitoring, The spikes are pressed into the ground surface and the geophone is stablized with sand bags.

For longer term monitoring, the spikes and geophone are pressed into the bottom of a shallow pit and buried.

Slab Installation

Most geophones have through-holes for anchors installed in the structure. The geophone is slipped onto a threaded anchor and held in place by a washer and tightened nut.

Horizontal geophones are always oriented with the arrow pointing toward the source of vibration.

Wall Installation

Vertical geophones are available for installation on walls. Vertical geophones should be oriented with the arrow pointing upward.

Wall-mount adaptors are available for horizontal geophones.

Damage to the facade can be avoided by installing the anchor in the grout line.

Borehole Installation

The borehole geophone is lowered to depth with one axis oriented toward the source of vibration.

The borehole is backfilled to stabilize the geophone and ensure adequate coupling with the ground.

Sand backfill can be used in shallow boreholes. Deeper boreholes require grout backfill.