FLX-Rail Dynamic Deflection Sensor

The FLX-Rail sensor records the maximum vertical deflection of a rail under the load of a passing train. Datasheet

FLX-Rail® Dynamic Deflection Sensor

The FLX-Rail is a dynamic deflection sensor that records the maximum vertical deflection of a rail under the load of a passing train.

Applications

- Supplement measurements of static non-loaded rails with measurements of dynamically loaded rails.

- Document vertical deflection of rails with geometry conditions.

- Establish deflection baselines before start of construction.

- Detect increases in deflection due to weather events, fouled ballast, or developing geotechnical anomolies such as sinkholes and subsidence.

Operation

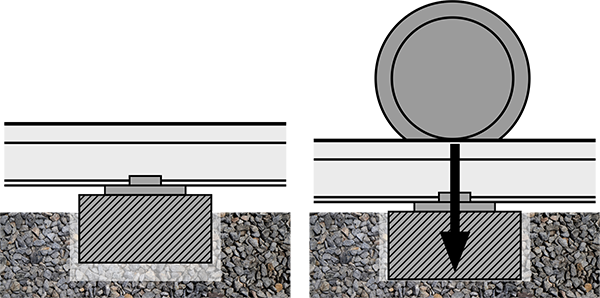

The FLX-Rail sensor uses an internal optical sensor to monitor the distance between a rail plate, which is magnetically clamped to the foot of the rail, and a reference plate, which contacts the ballast.

The sensor stays in a low-power standby mode until it detects vibrations from an approaching train. It then becomes active, continuously sampling the optical sensor at 350Hz. After the train has passed by, the sensor stores the maximum measured deflection, transmits the measurement to a wireless gateway, and re-enters standby mode.

Installation

FLX-Rail sensors should be installed in pairs, with one sensor for each rail. This provides deflection data for the two rails and also allows calculation of cross rail differences.

If a pipe is jacked under the track, the sensor pair would probably be located above the centerline of the pipe. To monitor longer spans, such as excavations along the track, three pairs of FLX-Rail sensors might be installed, one pair at the center point and the two other pairs at the end points of the specified chord length.

Installation requires choosing a location, clearing away a small amount of ballast under the rail, cleaning the underside of the rail for good magnet contact, then sliding the sensor into place and adjusting the initial spacing between the rail plate and the reference plate.

Advantages

Simple Installation: FLX-Rail sensors are easy to install. They are self- powered, waterproof, and report at scheduled intervals.

Void Detection: FLX-Rail sensors measure the elastic deflection of loaded rails and can reveal existing faults in the trackbed that cannot be detected by static measurements of unloaded rails.

Compliance: Measurements of any visible rail movement that occurs while the track is loaded must be added to measurements of the unloaded track. See Track and Rail and Infrastructure Compliance Manual, p 2.1.24. Office of Railroad Safety, Federal Rail Administration.

FLX-Rail® is a registered trademark of SISGEO SRL.

Specifications and photo courtesy of SISGEO.

The FLX-Rail sensor records the maximum deflection of dynamically loaded track.

Void or fault in ballast is detected only when track is loaded.

Specifications

Sensor Type: Internal optics.

Range: 2.75" (70 mm).

Resolution: 0.004" (0.01 mm).

Repeatability: ±0.004" (±0.01 mm).

Accuracy: <±0.004" (<±0.1 mm).

Reading Frequency: 350 Hz.

Data Storage: Up to 90 days of maximum deflection measurements.

Communications: RS-485 bus. Most systems forward data to a GeoCloud website using cellular modems.

Dimensions: Rail foot to top of sensor: 5.6" (142 mm). Rail plate to reference plate: 3.35" (85mm).

Environmental: –30°C to +70°C, IP 67.

Materials: Aluminum, stainless steel, galvanized steel, special compound of polycarbonate.

Battery Life: 8 months with rechargeable batteries, 45 months with non- rechargeable batteries. Battery usage assumes 100 transits of 15 second duration and 6 transmissions per day.

Management App: Used to set reading parameters and GPS position. Requires Android device.

GeoCloud Website: Measurements from all monitoring systems at the site are processed and presented graphically on a secure GeoCloud project website. Alerts are sent if measurements exceed preset alarm thresholds.