Settlement Plates

Settlement plates are used to monitor settlement induced by surcharges placed on compressible soils. Datasheet

Applications

Settlement plates are simple instruments that provide direct measurements of settlement beneath placed fills. Typical applications include:

- Monitoring consolidation of ground treated with wick drains and surcharges.

- Monitoring settlement of foundation soil during construction of embankments.

Components

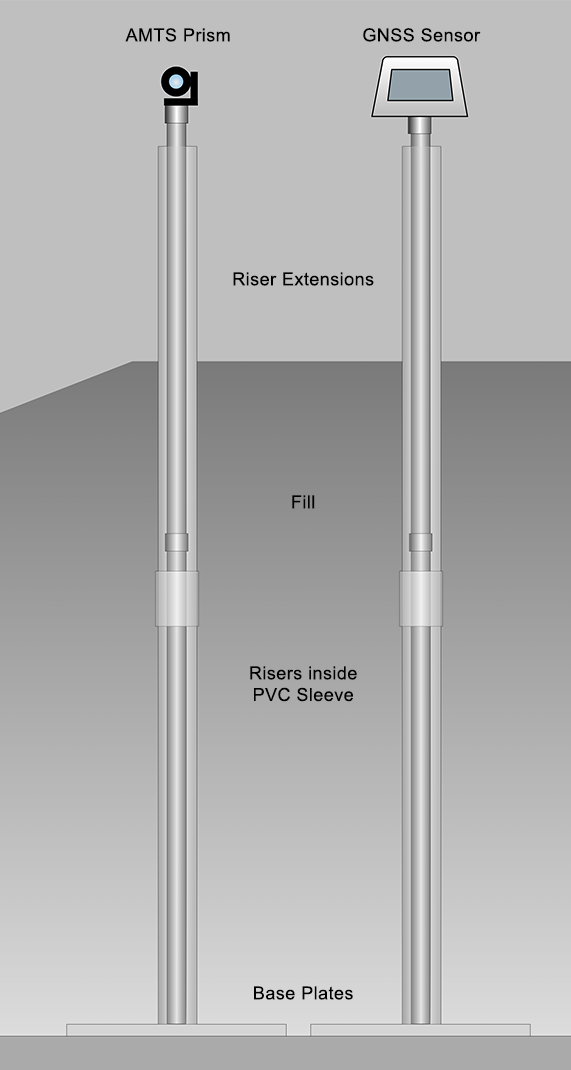

- Base Plate: 24 x 24 x 0.25 inch steel plate with

connection for riser. - Riser: 1-inch threaded steel pipe, typically supplied in 5-foot lengths. Threads allow extensions to be added.

- Sleeve: 1.5-inch PVC, typically supplied in 5 foot length. Optional or required, depending on project specifications.

- Riser Extensions: Riser & sleeve extensions, with couplings, required as height of fill increases.

- Prism or GNSS Sensor fitted to top of riser.

Installation & Maintenance

Settlement plates are installed at specified locations. Initial elevations of the plates and risers are noted.

Fill is hand-compacted around the riser to the specified level of the first lift. Paint, flags, cones, or fences are used to make the riser visible to equipment operators.

A riser extension is added when fill approaches the top of the existing riser. The prism or GNSS sensor is moved to the top of the extension and new offset is noted. Fill is again hand-compacted around the riser to the specified level of the next lift.

Monitoring Settlement Plates

Traditional: Settlement plates are traditionally monitored by a surveyor, who measures the elevation of the top of each riser. Each set of elevation measurements requires a visit by the surveyor, who then prepares and delivers a report.

AMTS Automation: Risers are fitted with prisms. An AMTS system automatically measures and transmits prism elevations to the internet. A GeoCloud website displays data and graphs.

GNSS Automation: Risers are fitted with GNSS sensors. Geodetic observations are automatically transmitted to the internet and visualized on a GeoCloud website.

Advantages of Automation

Safety and Cost Control: Automation helps control costs and enhance site safety by reducing the need for site visits by non-essential personnel, such as instrument technicians and survey crews. Site visits are required only for maintenance.

Reliable & Timely Measurements: Automation increases reliability and confidence in the data by obtaining measurements at frequent intervals.

Easy Access to Data: Automation allows measurements to be presented visually as graphs and status views on secure project websites.

AMTS System

The AMTS system (left) is mounted on a gravity base tower to provide good sight-lines to prisms that are installed on the settlement plate risers (above).

GNSS System

The GNSS sensor installed on the settlement plate riser (above) reports its geodetic observation directly to the Cloud for processing.